- DPDS limit switch for multiple applications

- Rugged aluminum alloy diecast housing

- High mechanical strength

- Oil resistance,waterproof and dustproof structure

Ratings

|

Rated

voltage |

Noninductive Load (A) |

nductive Load (A)

|

|

Resistance Load

|

Lamp Load

|

Inductive Load

|

Motor Load

|

|

NC |

NO |

NC |

NO |

NC |

NO |

NC |

NO |

|

125VAC

250VAC |

5(0.1)

3 |

1.5

1 |

0.7

0.5 |

3

2 |

2.5

1.5 |

1.3

0.8 |

8VDC

14VDC

30VDC

125VDC

250VDC

|

5(0.1)

5(0.1)

4(0.1)

0.4

0.2

|

2

2

2

0.05

0.03

|

5

4

3

0.4

0.2

|

4

4

3

0.4

0.2

|

3

3

3

0.05

0.03 |

Characteristics

| Rating |

5A 125V,3A 250VAC |

| Operation speed |

1mm~1m/s |

Operating frequency |

Mechanical:120 operations/min.Electrical:30 operations/min. |

Contact resistance |

15m max.(initial) |

IInsulation resistance |

100m min. (at 500VDC) |

| Dielectric strength |

1000VAC, 50/60 Hz for 1 minute between terminals of the same polarity |

| 1500VAC, 50/60 Hz for 1 minute between current-carrying and non-current-carrying metal parts |

1500VAC, 50/60 Hz for 1 minute between each terminal and ground |

| Vibration |

110 to 55HZ,1.5mm double amplitude |

| Shock |

Mechanical:Approx.1000m/s2(Appprox.100G'S)

Electrical:Approx.500m/s2(Approx.50G'S) |

| Ambient temperature |

-10~+70 |

| Humidity |

<95% RH |

| Life |

Mechanical: 10,000,000 operations/min.

Electrical: 200,000 operations/min. |

| Weight |

Approx.360g(cable length 3m) Approx.540g(cable length 5m) |

| Degree of protection |

IP67 |

Operating Characteristics

|

Models |

EC-3101 |

EC-3102 |

EC-3103 |

EC-3104 |

EC-3110 |

EC-3111 |

EC-3112 |

EC-3113 |

EC-3169 |

|

OF(Max.) |

1200gf(11.77N) |

1200gf(11.77N) |

1200gf(11.77N) |

580gf(5.69N) |

1200gf(11.77N) |

1800gf(17.65N) |

1800gf(17.65N) |

1800gf(17.65N) |

150gf(1.47N) |

|

RF(Min.) |

450gf(4.41N) |

450gf(4.41N) |

450gf(4.41N) |

150gf(1.47N) |

450gf(4.41N) |

450gf(4.41N) |

450gf(4.41N) |

450gf(4.41N) |

- |

|

PT(Max.) |

1.8mm |

1.8mm |

1.8mm |

25 |

1.8mm |

1.8mm |

1.8mm |

1.8mm |

15 |

|

OT(Min.) |

3mm |

3mm |

3mm |

40 |

3mm |

3mm |

3mm |

3mm |

- |

|

MD(Max.) |

0.2mm |

0.2mm |

0.2mm |

3 |

0.2mm |

0.2mm |

0.2mm |

0.2mm |

- |

|

OP |

15.7+-1mm |

28.5+-1mm |

28.5+-1mm |

- |

28.5+-1mm |

24.9+-1mm |

34.3+-1mm |

34.3+-1mm |

- |

|

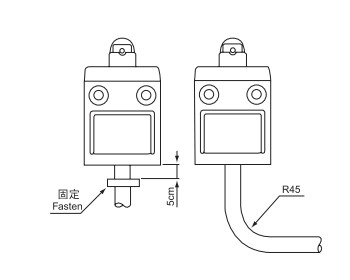

Fastening of the switch cable

The switch bodies are filled with resin for sealing purposes. To avoid stressing the cable and switch body, fasten the switch at 5 cm or farther away from the switch body, should the wire be bent, the bending radius shall be at least 45mm. |

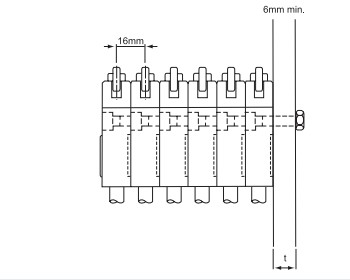

Switch bank mounting

A maximum of six switches may be mounted together as a switch bank. During the installation,the convex part of the switch back.The mounting panel shall be 6mm or thicker. |

|

|

|

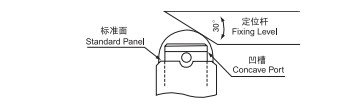

Installation The service life and accuracy of switches will be effected by the shape of actuator operation frequency & over travel. So the angular of the fixing level should be about 30, the surface finish of the fixing level should be over, the hardness is from HV400~500.When installing, the position of the concave part should be above the standard panel |

Installation

Recommended tightening torque according to the follwing form.

|

Model |

Screw type |

Torque |

|

1 |

M5 fastening screws

|

43.4~52lb.in

(50~60kgf.cm) |

|

2 |

M3.5 installing screws

|

6.9~7.9lb.in

(8~9kgf.cm) | |

|

|

|

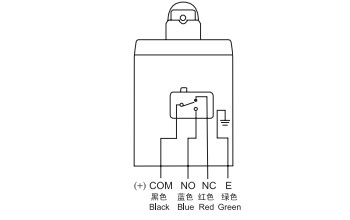

Contact types  |

Contact types

Mount the switch body to a rigid mounting panel using two M5 screws.

|

|